Vertically Integrated Manufacturing Capabilities

Product Line

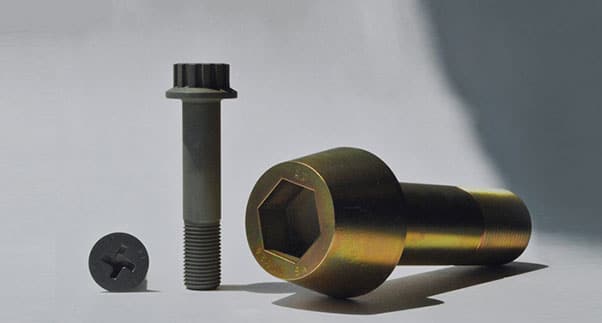

We produce close-tolerance, high-quality, high-temperature aerospace, and military fasteners, including screws, bolts, pins, and studs.

- Bolts (NSN Series 5306)

- Screws (NSN Series 5305)

- Pins (NSN Series 5315)

- Studs (NSN Series 5307)

- Threaded Rods

- Custom Specials

- AN

- MIL

- MS

- NAS

- NA

- Metric

Head Style Configurations

Aerospace Manufacturing produces all Head Style Configurations including, but not limited to the following:

- Spline Head

- 12 Point

- Socket Head

- Internal Wrenching

- Flush Head

- Hex Head

- Pan Head

- Six-Lobe

- Dovetail

- Shear Head

- Place Bolt

- Brazier Head

- Pin Head

- Round Head

- Slotted Round

- Crown Hex

- Slabbed

Recess Configurations

Aerospace Manufacturing manufactures fasteners with many types of Recess configuration including:

- Torq-Set® (Offset Cruciform)

- Torq-Set® ACR (Offset Cruciform-Ribbed)

- Phillips® (Cruciform)

- Hex Socket

- Phillips ACR®

- (Cruciform-Ribbed)

- Torx® (Six Lobed)

- Tri-Wing® (Tri-Slot)

- Dovetail Slot

- 6 Lobe

Raw Materials

- Super Alloys: Waspaloy™, Titanium 6-4 and 6-6, A-286, Inconel, 17-4PH, H-11, 15-5PH, 13-8MO, MP35N™ & MP159™, Monel 400 and 500

- Stainless Steel: 300 and 400 Series

- Alloy Steel: 8740, 4140, 4340 etc.

Process Capabilities

With forging presses, thread rolling machines, warm heading machine, and much more, AMI has the capabilities to perform: cutting-edge equipment includes, but is not limited to:

- Hot Forging

- Heat Treating

- Thread Rolling/Forming

- Centerless Grinding

- Machining

- Drilling

- Warm Heading – cold & warm

- Broaching

- Destructive and Non-Destructive Testing (NDT)

In-House Special Processes

- Heat Treating: In-house aging process

- Non-Destructive Testing (NDT) with Level II and Level III in-house certification.

- Plating/Finishing: Cadmium, cadmium fluorborate, passivation

Testing Capability

AMI’s commitment to quality is evident in our upgraded, modern, climate controlled Quality Control testing facility, which allows us to perform virtually all testing on-site. The proper equipment allows AMI to perform tension fatigue tests on specimens from a #10 screw up to 1-1/2 inch in diameter with a 260KSI UTS.

- Hardness Tests – HRC, superfcial & microhardness

- Metallography Tests

- Dimensional Inspections

- Double Shear Tests

- Tensile Strength Tests

- Stress Durability Tests

- Stress Rupture Tests

- Non-Destructing Testing (NDT) Level II and Level III inhouse certifed (MT, PT)

- Hydrogen Embrittlement Tests

Sikorsky Bolts & Screws

AMI is an approved manufacturer of Sikorsky bolts and screws. As a result, we also have a large inventory of finished products available. AMI is approved for the following Sikorsky Part Number – SS5213- on the following diameter sizes:

- SS5213-4

- SS5213-5 (2021)

- SS5213-7

- SS5213-9

- SS5213-10

- SS5213-12

If you have inquiries for Sikorsky items, we would be happy to quote them, and we may even have stock on them.