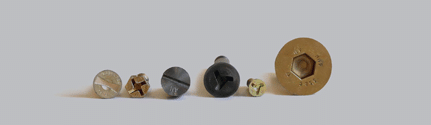

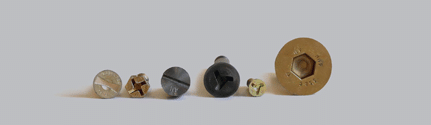

Established in New Jersey in 1986, AMI began as small manufacturer of complex fasteners focused on the production of bolts and screws.

In 1994, AMI added pins, studs, threaded rods and built-to-print specials to its fastener manufacturing capabilities, completing AMI’s standard fastener line manufactured to AN, MIL, MS, NA, and NAS standards. Exotic materials are also introduced to the product line.

Approved by Lockheed Martin Missiles & Space

Inauguration of a state-of-the-art, 6,000 square foot electro-plating facility

In-house laboratory inaugurated

Launch of new logo and website

Introduction of in-house tool and die making

Approved by BAE Systems, and Nordam

Approved by FAdeA, and KAMAN

AMI commemorates 30th anniversary with introduction of new logo and website

AMI becomes AS9100D:2016 certified Approved by SONACA Group

AMI celebrates 35-Year anniversary

By 1991, AMI had outgrown its first two facilities. AMI chose to invest in the refurbishment of 27,000 square foot original 1920’s sewing factory in Wallington, NJ, retrofitting it to a purpose-built-facility to enhance product flow.

Approved by Lockheed Missiles & Space Company

In 1997, AMI becomes QSLM approved for Class 2 and Class 3 fasteners.AMI successfully earned its ISO:9001, along with its Phillips Screw© license.

Approved by DSCP, NAVSUP for Class II and Class III Fasteners

Approved by Sikorsky Aircraft

Approved by BOEING Defense Space & Security, and Israel Aerospace Industries

Approved by Bombardier Aerospace

Approved by LMI Aerospace

Approved by Pilatus Aircraft, Blue Origin, and Arnprior Aerospace

Established in New Jersey in 1986, AMI began as small manufacturer of complex fasteners focused on the production of bolts and screws.

By 1991, AMI had outgrown its first two facilities. AMI chose to invest in the refurbishment of 27,000 square foot original 1920’s sewing factory in Wallington, NJ, retrofitting it to a purpose-built-facility to enhance product flow.

In 1994, AMI added pins, studs, threaded rods and built-to-print specials to its fastener manufacturing capabilities, completing AMI’s standard fastener line manufactured to AN, MIL, MS, NA, and NAS standards. Exotic materials are also introduced to the product line.

Approved by Lockheed Missiles & Space Company

In 1997, AMI becomes QSLM approved for Class 2 and Class 3 fasteners.AMI successfully earned its ISO:9001, along with its Phillips Screw© license.

Approved by Lockheed Martin Missiles & Space

Approved by DSCP, NAVSUP for Class II and Class III Fasteners

Inauguration of a state-of-the-art, 6,000 square foot electro-plating facility

In-house laboratory inaugurated

Launch of new logo and website

Introduction of in-house tool and die making

Approved by Sikorsky Aircraft

Approved by BOEING Defense Space & Security, and Israel Aerospace Industries

Approved by BAE Systems, and Nordam

Approved by Bombardier Aerospace

Approved by FAdeA, and KAMAN

Approved by LMI Aerospace

AMI commemorates 30th anniversary with introduction of new logo and website

AMI becomes AS9100D:2016 certified Approved by SONACA Group

AMI celebrates 35-Year anniversary

Approved by Pilatus Aircraft, Blue Origin, and Arnprior Aerospace

Company History

AMI has earned a solid reputation for reliability and high quality, making AMI a trusted source for world-class OEM leaders including, but not limited to Bombardier, BAE Systems, Lockheed Martin, Sikorsky Aircraft, NAVICP, NASA and Textron Aviation, to name just a few.